FACILITY, TOOLING & EQUIPMENT SUPPORT

FACILITY, TOOLING & EQUIPMENT SUPPORT

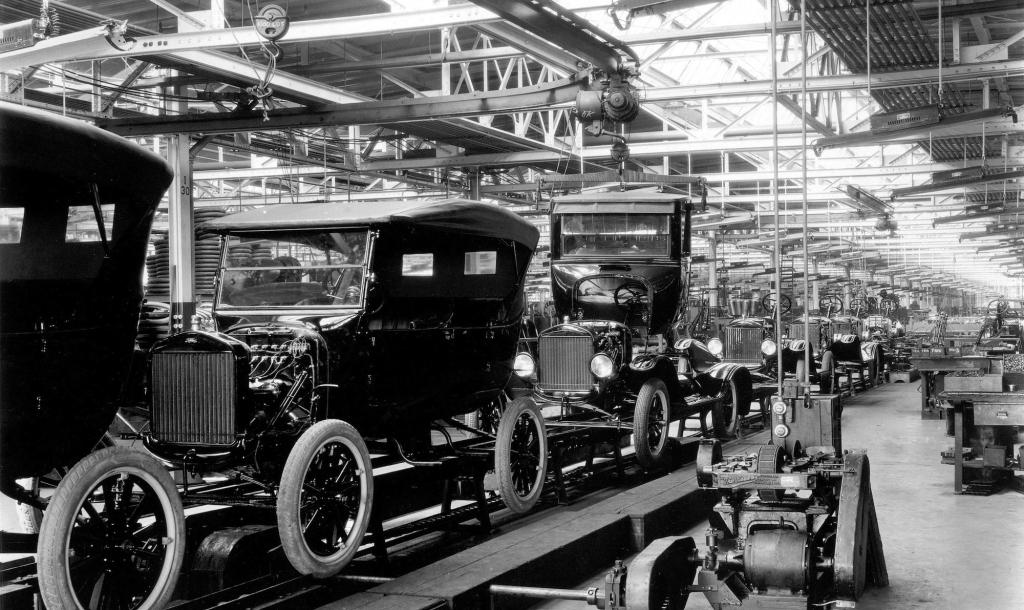

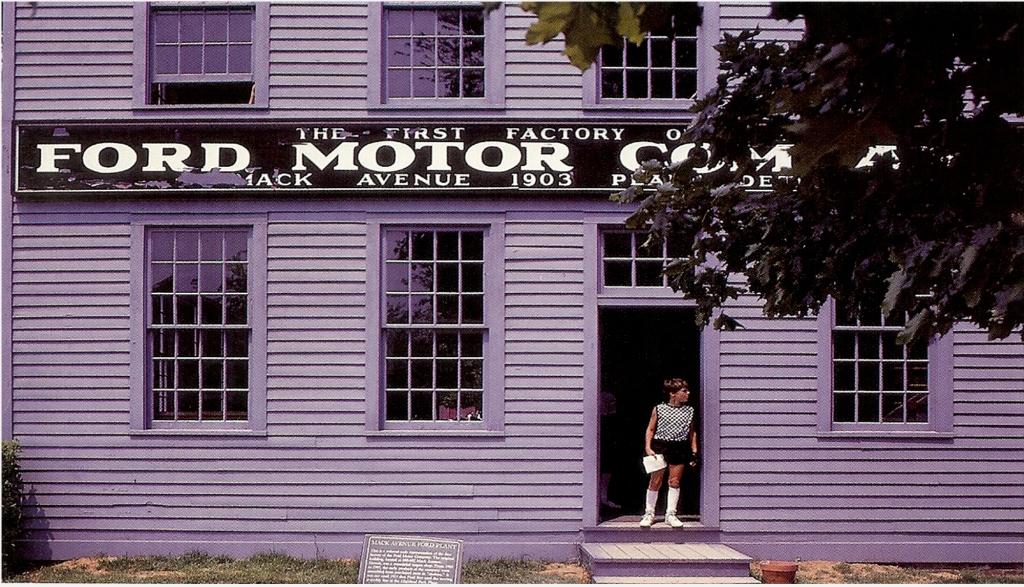

EVERY PROCESS NEEDS FACILITY

Introduction

The Farmer Group offers services which help support the integration of facility and process equipment with the product requirements of a new model launch program. This is accomplished by providing management and technical resources to define and implement the support aspects of a design and construction / installation program.

Members of the firm bring a diverse and detailed knowledge of a variety of project types involving facility, manufacturing and industrial analysis, required to bring a launch program to Job No.1 and beyond while maintaining predetermined quality, cost and timing targets. We understand assembly and manufacturing process and the facility requirements that such processes depend on. We can manage your construction and installation programs.

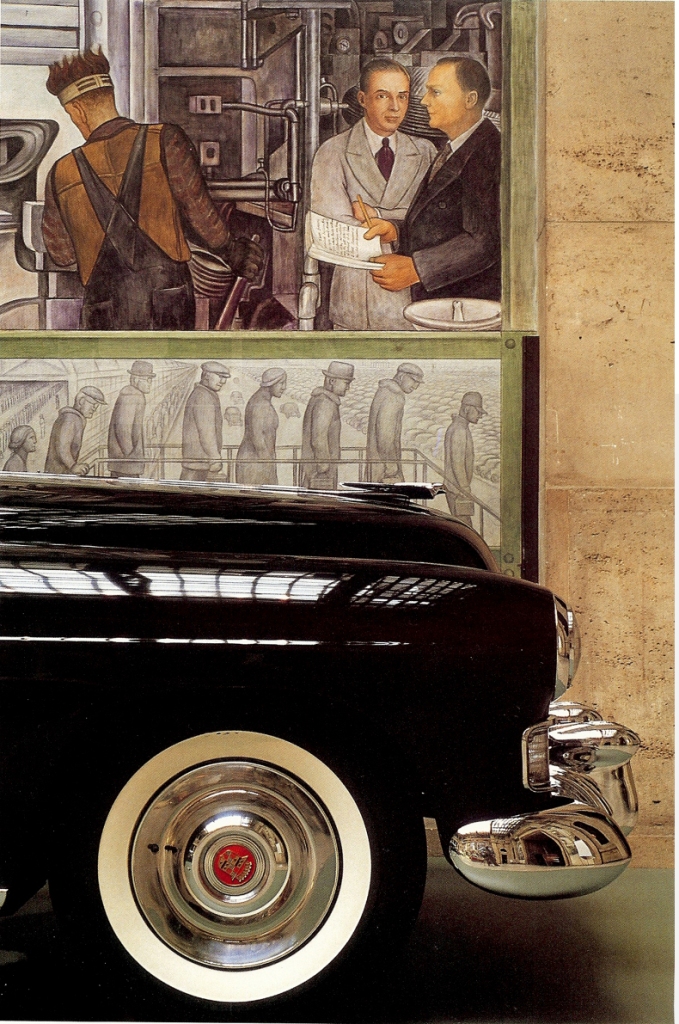

Paint, Finishes & Coatings Support

The Farmer Group provides its Customers paint process design and improvement services, including ongoing paint shop maintenance. We can help our customers specify finish and coating products that provide superior response, durability and meet quality objectives as well as being environmentally responsible.

We additionally support improvement initiatives to maintain spray booth and oven environments at optimum levels so that expensive coatings go on the product and not out the exhaust stacks. Through the robust control and monitoring of such key operating parameters as temperature, humidity, water flow and distribution, we are able to create significant quality improvements and cost savings opportunities. We offer cutting edge technologies in the arena of filtration engineering and equipment. The Farmer Group creates additional cost savings through improvements in eliminator efficiency, downdraft and zone to zone air balance, and painting efficiency through hardware upgrades, filtration improvements and improved operator training including operational support.

Facility Support Services

- Manufacturing Master Planning

- Construction Management

- Process Design

- Energy Management

- Equipment Installation & Fit-up Engineering

- Cost Estimating

- Concept Alternatives & Advanced Planning

- Plant Layout

- Design/Build Program Definition and Control

- Turn-Key Program Definition and Control

- Conveyor Engineering Design

- Material Handling Design

- Contractor Selection Assistance

- Equipment Selection & Specification

- Field Control & Support

Related Services

- General CADD Support Services

- Structural Design and Analysis

- Manufacturing Operation & Process Drawings

- Building Automation System

- Energy Management System

- Scheduling Optimization

- Forecasting Models

- Statistical Analysis and Experimental Design

Program Layouts, Bid Packages and Specifications

- Review Workability of Customer Layout

- Field Verification Services

- Detailed Program Layouts for Bid Issue

- Develop Mechanical & Electrical Requirements

- Develop Architectural, Civil & Structural Requirements

- Develop Energy Management Systems & Controls

- Contract Specifications

- Work Scope Definition,

- Long Lead Equipment Contingencies,

- Bidding Instructions and Standard Specifications

- Review Program Cost Estimates & Update

- Determine Line Lengths, Through-Put & Cycle Times

- Clearance Studies

- Develop Carrier Envelopes

- Coordinate Layout With Client Expectations

- Establish System Balance And Workability

- Manufacturing Simulation

- Determine Reuse of Existing Equipment

- Establish Quality Control Systems

- Ergonomics Design Considerations

- Provide Bid Documents to Various Contractors

- Issue Addenda During the Bidding Period

- Bid Analysis of Contractor Bids

- Approval of Contractor Drawings

35 W. Huron St., Suite 10 North, Pontiac, MI 48342 | 248-322-7079

Copyright ©2017 TheFarmerGroup Michigan Website Design by Design Source Media

Comments are closed.